Pallet racking system

VVN provides not only the delivery of pallet racks, but also helps to choose the most suitable solution according to the specification of each specific warehouse. Such an individual approach allows companies to use the premises as efficiently as possible and reduce the cost of storing goods.

Customers can be confident that the pallet racking solutions we offer are of high quality and will be built to withstand long-term loads and ensure cargo safety. "Viss otoktiem ud storagem" has many years of experience in the supply of pallet racks to companies in Latvia and abroad, and is one of the most important players in the warehouse equipment sector.

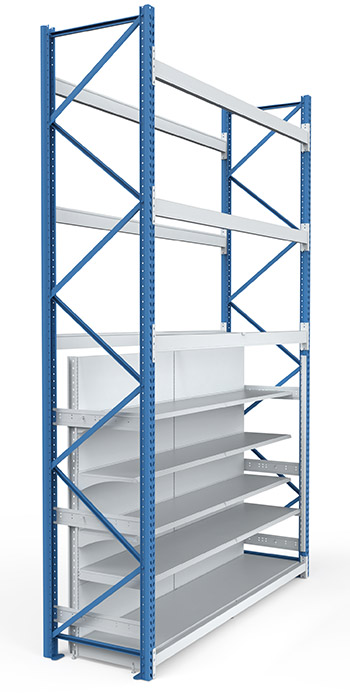

HX WAREHOUSE RACKS SYSTEM

The HX warehouse shelving system is designed and manufactured in accordance with international construc-tion standards. The shelves have a GS safety certificate, issued by the German institute TUV Rheinland. This certificate is a confir-mation that the shelves have been evaluated and tested for quality and safety according to strict German and European regulations.

TECHNICAL SPECIFICATION

|

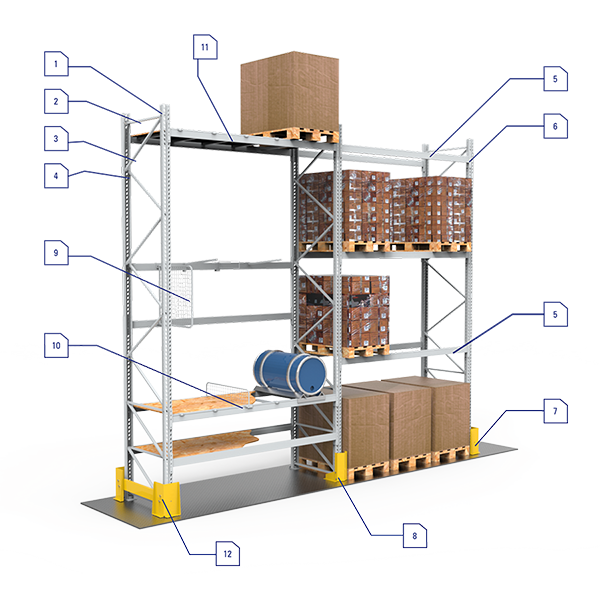

Basic components: 1 - pillar (profile, foot, screws with nuts); 2 - horizontal bracing; 3 - diagonal bracing; 4 - screw, nut, spacer sleeve (elements 1-4 form the frame (stand) of a rack); 5 - cross beam; 6 - cross beam- safeguard. Additional components: 7 - corner rack guard; 8 - front rack guard; 12 - fender beam. Accessories: 9, 10 - separators; 11 - crossbeam. |

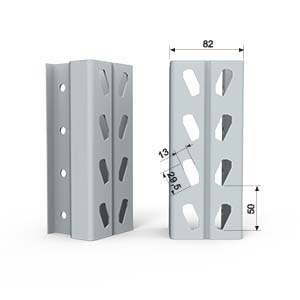

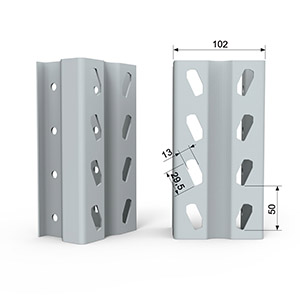

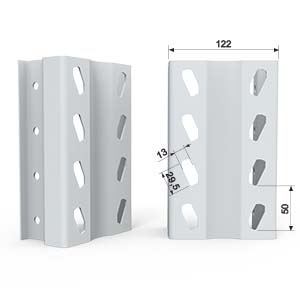

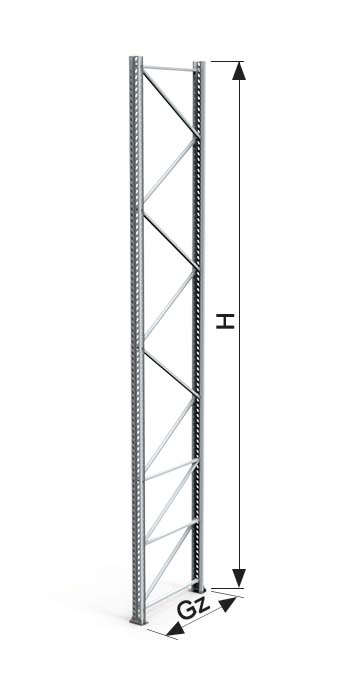

The HX system provides for a truss structure composed of two pillars joined by bracings. Pillars are made of perforated, steel open profiles with external dimensions of 82 × 70, 102 × 70 and 122 × 70 mm. The pillars include two rows of assembly openings positioned vertically every 50 mm.

|

|

|

| HX 82 PILLAR PROFILE | HX 102 PILLAR PROFILE | HX 122 PILLAR PROFILE |

The foot, which forms the frame’s basis, provides appropriate distribution of load to the floor and anchorage of the rack to the ground.

Bracings serve the purpose of joining two pillars into a frame. When it comes to a mounting method, we can distinguish two types of bracings:

• horizontal, mounted perpendicularly to pillars

• diagonal, mounted between two consecutive horizontal bracings.

The HX system provides for mounting of frames with two bracing systems, labelled as “S” and “ZZS”. The “ZZS” system allows distributing slightly greater loads than the “S” system.

The “ZZS” system considerably enhances resistance of the lower part of the pillar to destruction as a result of being hit by a forklift.

|

|

| HX FRAME WITH A “ZZS” BRACING SYSTEM | HX FRAME WITH AN “S” BRACING SYSTEM |

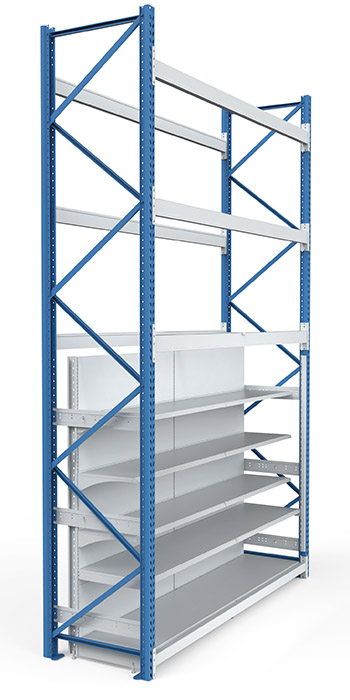

INTEGRATION OF STORE AND WAREHOUSE RACKS

A series of HX racks, mainly used for fitting high storage warehouses, can also be used to arrange sales areas. Application of relevant series of types of frames and traverses allows building structures that constitute a functional reflection of racks used by DIY (do-it-yourself) concepts or DIY discount stores. Application of a group of accessories perfectly meets expectations concerning exposure and sales in the abovementioned facilities.

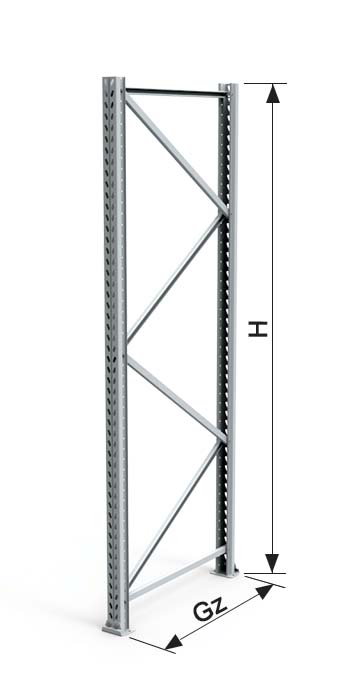

SINGLE INTEGRATION

FRAME WITH AREDUCE DEPTH 82 (S) LOWER TRAVERSE

|

|

HX 82 (S)

| Commercial depth Gh | Depth Gz [mm] | Integration Gh shelf | Height H [mm] |

| 810 | 780 | max. 670 | 4000 |

| 830 | 800 | max. 670 | 4000 |

| 910 | 880 | max. 570+210 | 4000 |

| 1050 | 1020 | max. 670+210 | 4000 |

| 1130 | 1100 | max. 670+210 | 4000 |

HX 102 (ZZS)

| Commercial depth Gh | Depth Gz [mm] | Integration Gh shelf | Height H [mm] |

| 810 | 780 | max. 670 | 4000 |

| 830 | 800 | max. 670 | 4000 |

| 910 | 880 | max. 570+210 | 4000 |

| 1050 | 1020 | max. 670+210 | 4000 |

| 1130 | 1100 | max. 670+210 | 4000 |

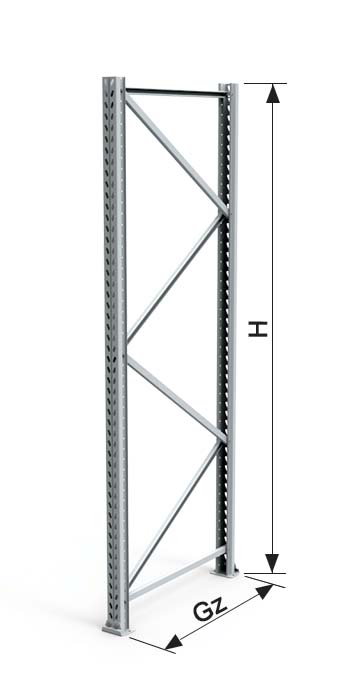

DOUBLE INTEGRATION

TWO FRAMES

|

|

|

FRAME 82 (S) DOUBLE INTEGRATION 2 FRAMES

| Commercial depth Gh | Depth Gz [mm] | Integration Gh shelf | Height H [mm] |

| 510 | 480 | max. 370 | 4400 4600 |

| 610 | 580 | max. 470 | 4400 4600 |

| 710 | 680 | max. 570 | 4400 4600 |

| 810 | 780 | max. 670 | 4400 4600 |

| 910 | 880 | max. 770 | 4400 4600 |

FRAME 102 (ZZS) DOUBLE INTEGRATION 2 FRAMES

| Commercial depth Gh | Depth Gz [mm] | Integration Gh shelf | Height H [mm] |

| 510 | 480 | max. 370 | 4400 |

| 610 | 580 | max. 470 | 4400 |

| 710 | 680 | max. 570 | 4400 |

| 810 | 780 | max. 670 | 4400 |

| 910 | 880 | max. 770 | 4400 |

TWO-SIDED INTEGRATION

TWO-SIDED INTEGRATION - GONDOLA IN ONE FRAME

|

HX 82

HX 102 (S)

HX 102 (ZZS)

|